- Reduced noise emissions according to future EU legislation on acoustic requirements

- Maximum acoustic tightness and temperature resistance at minimum weight

- In-house development and production, including innovative end-of-line test

Eberspaecher Exhaust Technology has developed a new generation of electrically operated acoustic valves for passenger cars. Thanks to maximum acoustic tightness and a continuously adjustable valve plate, it ensures lower levels of noise emissions and a pleasant vehicle sound. At the same time, the particularly lightweight valve efficiently reduces the muffler volume and exhaust back pressure. In-house production will start in 2020.

Stricter acoustic legislation targets will apply in the European Union in two years – and will be tightened still further in 2024. Thanks to the new acoustic valve, exhaust specialist Eberspaecher offers a future-proof solution for meeting tomorrow’s limit values and at the same time creating a pleasant vehicle sound. Automotive manufacturers also benefit from advantages in installation space: Due to its outstanding performance, the Eberspaecher acoustic valve minimizes the muffler volume by up to 30 percent – leaving more installation space for additional components while guaranteeing the same level of noise reduction.

Efficient reduction of noise emissions and exhaust back pressure

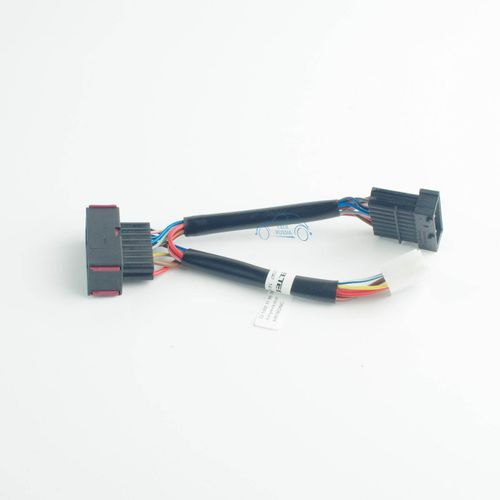

Compared to its previous version the new valve scores with maximum acoustic tightness and a valve plate that can be continuously adjusted between 0 and 90 degrees. At low speeds, e.g. when driving in built-up areas, it ensures the amount of exhaust gas flowing through the muffler is kept to a level that minimizes annoying noise. Additionally, flexible adjustment of the valve plate ensures a pleasant vehicle sound. At higher driving speeds, such as on the freeway, the open valve directs the exhaust gas outwards to the exhaust pipes. This reduces fuel consumption, lowers exhaust back pressure, and enables unrestricted engine power at high speed.

Lighter, tighter, and more robust

From development through to production of the acoustic valve – the entire product engineering process is taking place at Eberspaecher for the first time. Customers thus benefit from the high quality standards of the German exhaust specialists, who, among other things, use innovative laser technology to ensure an even lighter, tighter, and more robust valve. Use of hard-wearing plastic instead of metal and the very slim connecting element of the innovative actuator not only help to save weight but also reduce heat transfer: The 530-gram valve is particularly lightweight and designed for exhaust gas temperatures of 800 degrees Celsius and at least three million switching operations. The Esslingen-based company has also refined an end-of-line test (EOL test) to guarantee a long-lasting and perfect vehicle sound: For the first time, the innovative measuring method allows an assessment of the acoustic performance of the valve based on components – therefore, only acoustically effective valves leave the Eberspaecher plant.